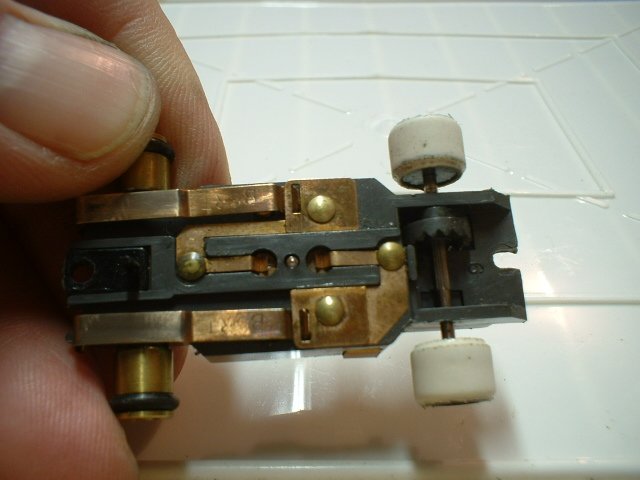

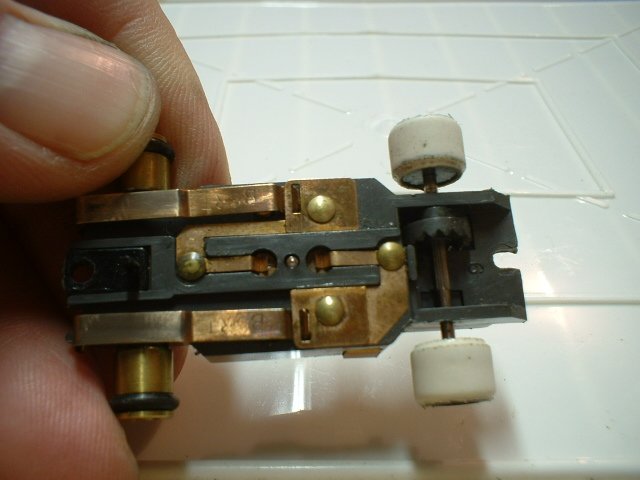

I next tried a drill blank axle, .0635, running down to 4.070 in 30 laps.

Next a Rabbit Racing .0635 stainless steel tubular axle went on, still with a stock gear. This axle weighs .2 gm, compared to .4 for the drill blank axle and .6 for the Super G+ axle. It ran a 4.073 after breaking in.

The next trial was the Rabbit axle with the AFX Specialty gear. I glued 4 .020 spacers to the back of the gear, inorder for it to work with the 9 tooth driven pinion gear. This setup ran 4.052 in 30 laps.

Staying with Rabbit axle, I put on Larry Thomas' Black Magic crown gear. Here is Larry's break in instructions:

For best performance, I recommend the following: Using a Tyco axle, I check the lateral movement of the rear axle with the crown gear and gearplate installed. I shoot for .008" / .012" lateral movement. Sand or shim the boss if necessary. (Usually not required.) I then shim the inside of the gear so that there is between .002" / .004" lateral movement in the rear axle. My goal is .002" but that is rather difficult to get every time. Then I replace the Tyco axle with my final racing axle. For break-in, I run the car 'gently' (slow to moderate speeds) around the track for 15 - 20 laps -- gears dry. After that, oil her up and let her rip! You should be able to get pretty darn close to maximum performance out of the gear at that time. One of the best shims I have run across is a stainless steel flat washer for a #1 screw. They are about .015" thick and I find that I usually need from .045" to .050" of shim on the inside. A layer of super glue, gel or thin, between the washers is a quick and easy way to add a couple of thousandths to the thickness of the washers. Works sweet!After the prescribed break in procedure, the LT gear ran 4.067 in 30 laps.

Wizzard .340 greens went on, replacing the Slottech .350...and ran 4.060 in 30 laps.

Scott Dunlap's .318 whites went on for a run...getting 4.086 in 30 laps.

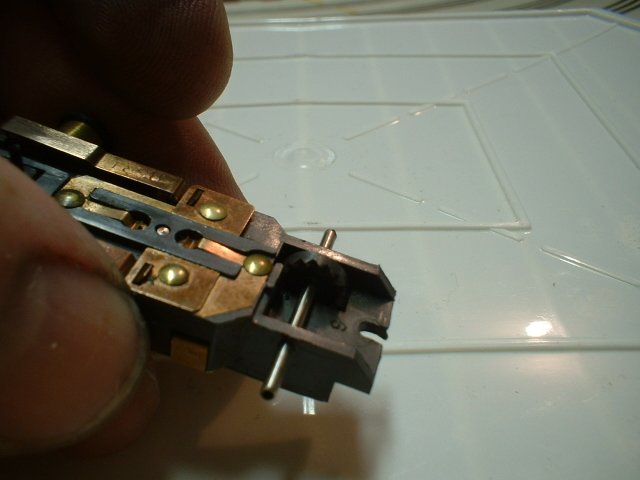

This shows the stock T-Jet crown on the left, the AFX Specialty crown in the middle and the Larry Thomas Black Magic crown on the right.

The stock gear measured .309, the AFX Specialty crown is .278 and the LT Black Magic is .298.

To sum up my testing, I found little difference between drill blank axles and stainless steel axles. The SS axles are lighter and non-magnetic, which should be an advantage. The drill blank feels the attraction from the rear magnet...but I really didn't see a lap time difference. Gear wise, also very little difference was apparent between the stock, AFX and LT gears. Tire wise the Slottech and Wizzard Greens were also pretty close in performance. >>>...Tom